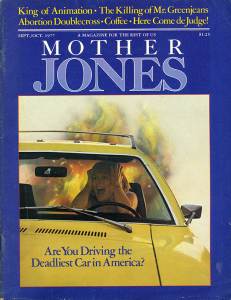

The following piece is the full Mother Jones Ford Pinto Madness Article 1977 that was largely responsible for Ford Motor Company’s Pinto Scandal of the 1970’s and 80’s, which has become somewhat of a cult status case concerning reputation management and corporate social responsibility.

The following piece is the full Mother Jones Ford Pinto Madness Article 1977 that was largely responsible for Ford Motor Company’s Pinto Scandal of the 1970’s and 80’s, which has become somewhat of a cult status case concerning reputation management and corporate social responsibility.

Prior to this article Ford had largely been arrogant and bullish in it’s handling of the crisis that was unfolding and whilst ultimately Ford survived the scandal and became a better company, later regarded for its corporate social responsibility this article and the events surrounding it are a case study in point about how not to deal with a crisis.

A Mother Jones Classic: For seven years the Ford Motor Company sold cars in which it knew hundreds of people would needlessly burn to death. MARK DOWIESEPTEMBER/OCTOBER 1977 ISSUE

(source: www.motherjones.com/politics/1977/09/pinto-madness/)

One evening in the mid-1960s, Arjay Miller was driving home from his office in Dearborn, Michigan, in the four-door Lincoln Continental that went with his job as president of the Ford Motor Company. On a crowded highway, another car struck his from the rear. The Continental spun around and burst into flames. Because he was wearing a shoulder-strap seat belt, Miller was unharmed by the crash, and because his doors didn’t jam he escaped the gasoline-drenched, flaming wreck. But the accident made a vivid impression on him. Several months later, on July 15, 1965, he recounted it to a U.S. Senate subcommittee that was hearing testimony on auto safety legislation. “I still have burning in my mind the image of that gas tank on fire,” Miller said. He went on to express an almost passionate interest in controlling fuel-fed fires in cars that crash or roll over. He spoke with excitement about the fabric gas tank Ford was testing at that very moment. “If it proves out,” he promised the senators, it will be a feature you will see in our standard cars.”

Almost seven years after Miller’s testimony, a woman, whom for legal reasons we will call Sandra Gillespie, pulled onto a Minneapolis highway in her new Ford Pinto. Riding with her was a young boy, whom we’ll call Robbie Carlton. As she entered a merge lane, Sandra Gillespie’s car stalled. Another car rear-ended hers at an impact speed of 28 miles per hour. The Pinto’s gas tank ruptured. Vapors from it mixed quickly with the air in the passenger compartment. A spark ignited the mixture and the car exploded in a ball of fire. Sandra died in agony a few hours later in an emergency hospital. Her passenger, 13-year-old Robbie Carlton, is still alive; he has just come home from another futile operation aimed at grafting a new ear and nose from skin on the few unscarred portions of his badly burned body. (This accident is real; the details are from police reports.)

Why did Sandra Gillespie’s Ford Pinto catch fire so easily, seven years after Ford’s Arjay Miller made his apparently sincere pronouncements—the same seven years that brought more safety improvements to cars than any other period in automotive history? An extensive investigation by Mother Jones over the past six months has found these answers:

- Fighting strong competition from Volkswagen for the lucrative small-car market, the Ford Motor Company rushed the Pinto into production in much less than the usual time.

- Ford engineers discovered in pre-production crash tests that rear-end collisions would rupture the Pinto’s fuel system extremely easily.

- Because assembly-line machinery was already tooled when engineers found this defect, top Ford officials decided to manufacture the car anyway—exploding gas tank and all—even though Ford owned the patent on a much safer gas tank.

- For more than eight years afterwards, Ford successfully lobbied, with extraordinary vigor and some blatant lies, against a key government safety standard that would have forced the company to change the Pinto’s fire-prone gas tank.By conservative estimates Pinto crashes have caused 500 burn deaths to people who would not have been seriously injured if the car had not burst into flames. The figure could be as high as 900. Burning Pintos have become such an embarrassment to Ford that its advertising agency, J. Walter Thompson, dropped a line from the end of a radio spot that read “Pinto leaves you with that warm feeling.”Ford knows the Pinto is a firetrap, yet it has paid out millions to settle damage suits out of court, and it is prepared to spend millions more lobbying against safety standards. With a half million cars rolling off the assembly lines each year, Pinto is the biggest-selling subcompact in America, and the company’s operating profit on the car is fantastic. Finally, in 1977, new Pinto models have incorporated a few minor alterations necessary to meet that federal standard Ford managed to hold off for eight years. Why did the company delay so long in making these minimal, inexpensive improvements?

- Ford waited eight years because its internal “cost-benefit analysis,” which places a dollar value on human life, said it wasn’t profitable to make the changes sooner.Before we get to the question of how much Ford thinks your life is worth, let’s trace the history of the death trap itself. Although this particular story is about the Pinto, the way in which Ford made its decision is typical of the U.S. auto industry generally. There are plenty of similar stories about other cars made by other companies. But this case is the worst of them all.The next time you drive behind a Pinto (with over two million of them on the road, you shouldn’t have much trouble finding one), take a look at the rear end. That long silvery object hanging down under the bumper is the gas tank. The tank begins about six inches forward of the bumper. In late models the bumper is designed to withstand a collision of only about five miles per hour. Earlier bumpers may as well not have been on the car for all the protection they offered the gas tank.Mother Jones has studied hundreds of reports and documents on rear-end collisions involving Pintos. These reports conclusively reveal that if you ran into that Pinto you were following at over 30 miles per hour, the rear end of the car would buckle like an accordion, right up to the back seat. The tube leading to the gas-tank cap would be ripped away from the tank itself, and gas would immediately begin sloshing onto the road around the car. The buckled gas tank would be jammed up against the differential housing (that big bulge in the middle of your rear axle), which contains four sharp, protruding bolts likely to gash holes in the tank and spill still more gas. Now all you need is a spark from a cigarette, ignition, or scraping metal, and both cars would be engulfed in flames. If you gave that Pinto a really good whack—say, at 40 mph—chances are excellent that its doors would jam and you would have to stand by and watch its trapped passengers burn to death.

This scenario is no news to Ford. Internal company documents in our possession show that Ford has crash-tested the Pinto at a top-secret site more than 40 times and that every test made at over 25 mph without special structural alteration of the car has resulted in a ruptured fuel tank. Despite this, Ford officials denied under oath having crash-tested the Pinto.

Eleven of these tests, averaging a 31-mph impact speed, came before Pintos started rolling out of the factories. Only three cars passed the test with unbroken fuel tanks. In one of them an inexpensive light-weight plastic baffle was placed between the front of the gas tank and the differential housing, so those four bolts would not perforate the tank. (Don’t forget about that little piece of plastic, which costs one dollar and weighs one pound. It plays an important role in our story later on.) In another successful test, a piece of steel was placed between the tank and the bumper. In the third test car the gas tank was lined with a rubber bladder. But none of these protective alterations was used in the mass-produced Pinto.

In pre-production planning, engineers seriously considered using in the Pinto the same kind of gas tank Ford uses in the Capri. The Capri tank rides over the rear axle and differential housing. It has been so successful in over 50 crash tests that Ford used it in its Experimental Safety Vehicle, which withstood rear-end impacts of 60 mph. So why wasn’t the Capri tank used in the Pinto? Or, why wasn’t that plastic baffle placed between the tank and the axle—something that would have saved the life of Sandra Gillespie and hundreds like her? Why was a car known to be a serious fire hazard deliberately released to production in August of 1970?

Whether Ford should manufacture subcompacts at all was the subject of a bitter two-year debate at the company’s Dearborn headquarters. The principals in this corporate struggle were the then-president Semon “Bunky” Knudsen, whom Henry Ford II had hired away from General Motors, and Lee Iacocca, a spunky Young Turk who had risen fast within the company on the enormous success of the Mustang. Iacocca argued forcefully that Volkswagen and the Japanese were going to capture the entire American subcompact market unless Ford put out its own alternative to the VW Beetle. Bunky Knudsen said, in effect: let them have the small-car market; Ford makes good money on medium and large models. But he lost the battle and later resigned. Iacocca became president and almost immediately began a rush program to produce the Pinto.

Like the Mustang, the Pinto became known in the company as “Lee’s car.” Lee Iococca wanted that little car in the showrooms of America with the 1971 models. So he ordered his engineering vice president, Bob Alexander, to oversee what was probably the shortest production planning period in modern automotive history. The normal time span from conception to production of a new car model is about 43 months. The Pinto schedule was set at just under 25.

A quick glance at the bar chart below will show you what that speed-up meant. Design, styling, product planning,advance engineering and quality assurance all have flexible time frames, and engineers can pretty much carry these on simultaneously. Tooling, on the other hand, has a fixed time frame of about 18 months. Normally, an auto company doesn’t begin tooling until the other processes are almost over: you don’t want to make the machines that stamp and press and grind metal into the shape of car parts until you know all those parts will work well together. But Iacocca’s speed-up meant Pinto tooling went on at the same time as product development. So when crash tests revealed a serious defect in the gas tank, it was too late. The tooling was well under way.

When it was discovered the gas tank was unsafe, did anyone go to Iacocca and tell him? “Hell no,” replied an engineer who worked on the Pinto, a high company official for many years, who, unlike several others at Ford, maintains a necessarily clandestine concern for safety. “That person would have been fired. Safety wasn’t a popular subject around Ford in those days. With Lee it was taboo. Whenever a problem was raised that meant a delay on the Pinto, Lee would chomp on his cigar, look out the window and say ‘Read the product objectives and get back to work.’”

The product objectives are clearly stated in the Pinto “green book.” This is a thick, top-secret manual in green covers containing a step-by-step production plan for the model, detailing the metallurgy, weight, strength and quality of every part in the car. The product objectives for the Pinto are repeated in an article by Ford executive F.G. Olsen published by the Society of Automotive Engineers. He lists these product objectives as follows:

1. TRUE SUBCOMPACT

- Size

- Weight2. LOW COST OF OWNERSHIP

- Initial price

- Fuel consumption

- Reliability

- Serviceability3. CLEAR PRODUCT SUPERIORITY

- Appearance

- Comfort

- Features

- Ride and Handling

- PerformanceSafety, you will notice, is not there. It is not mentioned in the entire article. As Lee Iacocca was fond of saying, “Safety doesn’t sell.”

Heightening the anti-safety pressure on Pinto engineers was an important goal set by Iacocca known as “the limits of 2,000.” The Pinto was not to weigh an ounce over 2,000 pounds and not to cost a cent over $2,000. “Iacocca enforced these limits with an iron hand,” recalls the engineer quoted earlier. So, even when a crash test showed that that one-pound, one-dollar piece of plastic stopped the puncture of the gas tank, it was thrown out as extra cost and extra weight.

People shopping for subcompacts are watching every dollar. “You have to keep in mind,” the engineer explained, “that the price elasticity on these subcompacts is extremely tight. You can price yourself right out of the market by adding $25 to the production cost of the model. And nobody understands that better than Iacocca.”

Dr. Leslie Ball, the retired safety chief for the NASA manned space program and a founder of the International Society of Reliability Engineers, recently made a careful study of the Pinto. “The release to production of the Pinto was the most reprehensible decision in the history of American engineering,” he said. Ball can name more than 40 European and Japanese models in the Pinto price and weight range wit h safer gas-tank positioning. Ironically, many of them, like the Ford Capri, contain a “saddle-type” gas tank riding over the back axle. The patent on the saddle-type tank is owned by the Ford Motor Co.

Los Angeles auto safety expert Byron Bloch has made an in-depth study of the Pinto fuel system. “It’s a catastrophic blunder,” he says. “Ford made an extremely irresponsible decision when they placed such a weak tank in such a ridiculous location in such a soft rear end. It’s almost designed to blow up—premeditated.”

A Ford engineer, who doesn’t want his name used, comments: “This company is run by salesmen, not engineers; so the priority is styling, not safety.” He goes on to tell a story about gas-tank safety at Ford:

Lou Tubben is one of the most popular engineers at Ford. He’s a friendly, outgoing guy with a genuine concern for safety. By 1971 he had grown so concerned about gas-tank integrity that he asked his boss if he could prepare a presentation on safer tank design. Tubben and his boss had both worked on the Pinto and shared a concern for its safety. His boss gave him the go-ahead, scheduled a date for the presentation and invited all company engineers and key production planning personnel. When time came for the meeting, a grand total of two people showed up—Lou Tubben and his boss.

“So you see,” continued the anonymous Ford engineer ironically, “there are a few of us here at Ford who are concerned about fire safety.” He adds: “They are mostly engineers who have to study a lot of accident reports and look at pictures of burned people. But we don’t talk about it much. It isn’t a popular subject. I’ve never seen safety on the agenda of a product meeting and, except for a brief period in 1956, I can’t remember seeing the word safety in an advertisement. I really don’t think the company wants American consumers to start thinking too much about safety—for fear they might demand it, I suppose.”

Asked about the Pinto gas tank, another Ford engineer admitted: “That’s all true. But you miss the point entirely. You see, safety isn’t the issue, trunk space is. You have no idea how stiff the competition is over trunk space. Do you realize that if we put a Capri-type tank in the Pinto you could only get one set of golf clubs in the trunk?”

Blame for Sandra Gillespie’s death, Robbie Carlton’s unrecognizable face and all the other injuries and deaths in Pintos since 1970 does not rest on the shoulders of Lee Iacocca alone. For, while he and his associates fought their battle against a safer Pinto in Dearborn, a larger war against safer cars raged in Washington. One skirmish in that war involved Ford’s successful eight-year lobbying effort against Federal Motor Vehicle Safety Standard 301, the rear-end provisions of which would have forced Ford to redesign the Pinto.

But first some background:

During the early ’60s, auto safety legislation became the bête-noire of American big business. The auto industry was the last great unregulated business, and if it couldn’t reverse the tide of government regulation, the reasoning went, no one could.

People who know him cannot remember Henry Ford II taking a stronger stand than the one he took against the regulation of safety design. He spent weeks in Washington calling on members of Congress, holding press conferences and recruiting business cronies like W.B. Murphy of Campbell’s Soup to join the anti-regulation battle. Displaying the sophistication for which today’s American corporate leaders will be remembered, Murphy publicly called auto safety “a hula hoop, a fad that will pass.” He was speaking to a special luncheon of the Business Council, an organization of 100 chief executives who gather periodically in Washington to provide “advice” and “counsel” to government. The target of their wrath in this instance was the Motor Vehicle Safety Bills introduced in both houses of Congress, largely in response to Ralph Nader’s Unsafe at Any Speed.

By 1965, most pundits and lobbyists saw the handwriting on the wall and prepared to accept government “meddling” in the last bastion of free enterprise. Not Henry. With bulldog tenacity, he held out for defeat of the legislation to the very end, loyal to his grandfather’s invention and to the company that makes it. But the Safety Act passed the House and Senate unanimously, and was signed into law by Lyndon Johnson in 1966.

While lobbying for and against legislation is pretty much a process of high-level back-slapping, press-conferencing and speech-making, fighting a regulatory agency is a much subtler matter. Henry headed home to lick his wounds in Grosse Pointe, Michigan, and a planeload of the Ford Motor Company’s best brains flew to Washington to start the “education” of the new federal auto safety bureaucrats.

Their job was to implant the official industry ideology in the minds of the new officials regulating auto safety. Briefly summarized, that ideology states that auto accidents are caused not by cars, but by 1) people and 2) highway conditions.

This philosophy is rather like blaming a robbery on the victim. Well, what did you expect? You were carrying money, weren’t you? It is an extraordinary experience to hear automotive “safety engineers” talk for hours without ever mentioning cars. They will advocate spending billions educating youngsters, punishing drunks and redesigning street signs. Listening to them, you can momentarily begin to think that it is easier to control 100 million drivers than a handful of manufacturers. They show movies about guardrail design and advocate the clear-cutting of trees 100 feet back from every highway in the nation. If a car is unsafe, they argue, it is because its owner doesn’t properly drive it. Or, perhaps, maintain it.

In light of an annual death rate approaching 50,000, they are forced to admit that driving is hazardous. But the car is, in the words of Arjay Miller, “the safest link in the safety chain.”

Before the Ford experts left Washington to return to drafting tables in Dearborn they did one other thing. They managed to informally reach an agreement with the major public servants who would be making auto safety decisions. This agreement was that “cost-benefit” would be an acceptable mode of analysis by Detroit and its new regulators. And, as we shall see, cost-benefit analysis quickly became the basis of Ford’s argument against safer car design.

Cost-benefit analysis was used only occasionally in government until President Kennedy appointed Ford Motor Company president Robert McNamara to be Secretary of Defense. McNamara, originally an accountant, preached cost-benefit with all the force of a Biblical zealot. Stated in its simplest terms, cost-benefit analysis says that if the cost is greater than the benefit, the project is not worth it—no matter what the benefit. Examine the cost of every action, decision, contract part or change, the doctrine says, then carefully evaluate the benefits (in dollars) to be certain that they exceed the cost before you begin a program or—and this is the crucial part for our story—pass a regulation.

As a management tool in a business in which profits matter over everything else, cost-benefit analysis makes a certain amount of sense. Serious problems come, however, when public officials who ought to have more than corporate profits at heart apply cost-benefit analysis to every conceivable decision. The inevitable result is that they must place a dollar value on human life.

Ever wonder what your life is worth in dollars? Perhaps $10 million? Ford has a better idea: $200,000.

Remember, Ford had gotten the federal regulators to agree to talk auto safety in terms of cost-benefit analysis. But in order to be able to argue that various safety costs were greater than their benefits, Ford needed to have a dollar value figure for the “benefit.” Rather than be so uncouth as to come up with such a price tag itself, the auto industry pressured the National Highway Traffic Safety Administration to do so. And in a 1972 report the agency decided a human life was worth $200,725. Inflationary forces have recently pushed the figure up to $278,000.

Furnished with this useful tool, Ford immediately went to work using it to prove why various safety improvements were too expensive to make.

Nowhere did the company argue harder that it should make no changes than in the area of rupture-prone fuel tanks. Not long after the government arrived at the $200,725-per-life figure, it surfaced, rounded off to a cleaner $200,000, in an internal Ford memorandum. This cost-benefit analysis argued that Ford should not make an $11-per-car improvement that would prevent 180 fiery deaths a year. (This minor change would have prevented gas tanks from breaking so easily both in rear-end collisions, like Sandra Gillespie’s, and in rollover accidents, where the same thing tends to happen.)

Ford’s cost-benefit table is buried in a seven-page company memorandum entitled “Fatalities Associated with Crash-Induced Fuel Leakage and Fires.” The memo argues that there is no financial benefit in complying with proposed safety standards that would admittedly result in fewer auto fires, fewer burn deaths and fewer burn injuries. Naturally, memoranda that speak so casually of “burn deaths” and “burn injuries” are not released to the public. They are very effective, however, with Department of Transportation officials indoctrinated in McNamarian cost-benefit analysis.

All Ford had to do was convince men like John Volpe, Claude Brinegar and William Coleman (successive Secretaries of Transportation during the Nixon-Ford years) that certain safety standards would add so much to the price of cars that fewer people would buy them. This could damage the auto industry, which was still believed to be the bulwark of the American economy. “Compliance to these standards,” Henry Ford II prophesied at more than one press conference, “will shut down the industry.”

The Nixon Transportation Secretaries were the kind of regulatory officials big business dreams of. They understood and loved capitalism and thought like businessmen. Yet, best of all, they came into office uninformed on technical automotive matters. And you could talk “burn injuries” and “burn deaths” with these guys, and they didn’t seem to envision children crying at funerals and people hiding in their homes with melted faces. Their minds appeared to have leapt right to the bottom line—more safety meant higher prices, higher prices meant lower sales and lower sales meant lower profits.

So when J. C. Echold, Director of Automotive Safety (which means chief anti-safety lobbyist) for Ford, wrote to the Department of Transportation—which he still does frequently, at great length—he felt secure attaching a memorandum that in effect says it is acceptable to kill 180 people and burn another 180 every year, even though we have the technology that could save their lives for $11 a car.

Furthermore, Echold attached this memo, confident, evidently, that the Secretary would question neither his low death/injury statistics nor his high cost estimates. But it turns out, on closer examination, that both these findings were misleading.

First, note that Ford’s table shows an equal number of burn deaths and burn injuries. This is false. All independent experts estimate that for each person who dies by an auto fire, many more are left with charred hands, faces and limbs. Andrew McGuire of the Northern California Burn Center estimates the ratio of burn injuries to deaths at ten to one instead of the one to one Ford shows here. Even though Ford values a burn at only a piddling $67,000 instead of the $200,000 price of a life, the true ratio obviously throws the company’s calculations way off.

The other side of the equation, the alleged $11 cost of a fire-prevention device, is also a misleading estimation. One document that was not sent to Washington by Ford was a “Confidential” cost analysis Mother Jones has managed to obtain, showing that crash fires could be largely prevented for considerably less than $11 a car. The cheapest method involves placing a heavy rubber bladder inside the gas tank to keep the fuel from spilling if the tank ruptures. Goodyear had developed the bladder and had demonstrated it to the automotive industry. We have in our possession crash-test reports showing that the Goodyear bladder worked well. On December 2, 1970 (two years before Echold sent his cost-benefit memo to Washington), Ford Motor Company ran a rear-end crash test on a car with the rubber bladder in the gas tank. The tank ruptured, but no fuel leaked. On January 15, 1971, Ford again tested the bladder and again it worked. The total purchase and installation cost of the bladder would have been $5.08 per car. That $5.08 could have saved the lives of Sandra Gillespie and several hundred others.

When a federal regulatory agency like the National Highway Traffic Safety Administration (NHTSA) decides to issue a new standard, the law usually requires it to invite all interested parties to respond before the standard is enforced—a reasonable enough custom on the surface. However, the auto industry has taken advantage of this process and has used it to delay lifesaving emission and safety standards for years. In the case of the standard that would have corrected that fragile Pinto fuel tank, the delay was for an incredible eight years.

The particular regulation involved here was Federal Motor Vehicle Safety Standard 301. Ford picked portions of Standard 301 for strong opposition way back in 1968 when the Pinto was still in the blueprint stage. The intent of 301, and the 300 series that followed it, was to protect drivers and passengers after a crash occurs. Without question the worst post-crash hazard is fire. So Standard 301 originally proposed that all cars should be able to withstand a fixed barrier impact of 20 mph (that is, running into a wall at that speed) without losing fuel.

When the standard was proposed, Ford engineers pulled their crash-test results out of their files. The front ends of most cars were no problem—with minor alterations they could stand the impact without losing fuel. “We were already working on the front end,” Ford engineer Dick Kimble admitted. “We knew we could meet the test on the front end.” But with the Pinto particularly, a 20-mph rear-end standard meant redesigning the entire rear end of the car. With the Pinto scheduled for production in August of 1970, and with $200 million worth of tools in place, adoption of this standard would have created a minor financial disaster. So Standard 301 was targeted for delay, and, with some assistance from its industry associates, Ford succeeded beyond its wildest expectations: the standard was not adopted until the 1977 model year. Here is how it happened:

There are several main techniques in the art of combating a government safety standard: a) make your arguments in succession, so the feds can be working on disproving only one at a time; b) claim that the real problem is not X but Y (we already saw one instance of this in “the problem is not cars but people”); c) no matter how ridiculous each argument is, accompany it with thousands of pages of highly technical assertions it will take the government months or, preferably, years to test. Ford’s large and active Washington office brought these techniques to new heights and became the envy of the lobbyists’ trade.

The Ford people started arguing against Standard 301 way back in 1968 with a strong attack of technique b). Fire, they said, was not the real problem. Sure, cars catch fire and people burn occasionally. But statistically auto fires are such a minor problem that NHTSA should really concern itself with other matters.

Strange as it may seem, the Department of Transportation (NHTSA’s parent agency) didn’t know whether or not this was true. So it contracted with several independent research groups to study auto fires. The studies took months, which was just what Ford wanted.

The completed studies, however, showed auto fires to be more of a problem than Transportation officials ever dreamed of. Robert Nathan and Associates, a Washington research firm, found that 400,000 cars were burning up every year, burning more than 3,000 people to death. Furthermore, auto fires were increasing five times as fast as building fires. Another study showed that 35 per cent of all fire deaths in the U.S. occurred in automobiles. Forty per cent of all fire department calls in the 1960s were to vehicle fires—a public cost of $350 million a year, a figure that, incidentally, never shows up in cost-benefit analyses.

Another study was done by the Highway Traffic Research Institute in Ann Arbor, Michigan, a safety think-tank funded primarily by the auto industry (the giveaway there is the words “highway traffic” rather than “automobile” in the group’s name). It concluded that 40 per cent of the lives lost in fuel-fed fires could be saved if the manufacturers complied with proposed Standard 301. Finally, a third report was prepared for NHTSA by consultant Eugene Trisko entitled “A National Survey of Motor Vehicle Fires.” His report indicates that the Ford Motor Company makes 24 per cent of the cars on the American road, yet these cars account for 42 per cent of the collision-ruptured fuel tanks.

Ford lobbyists then used technique a)—bringing up a new argument. Their line then became: yes, perhaps burn accidents do happen, but rear-end collisions are relatively rare (note the echo of technique b) here as well). Thus Standard 301 was not needed. This set the NHTSA off on a new round of analyzing accident reports. The government’s findings finally were that rear-end collisions were seven and a half times more likely to result in fuel spills than were front-end collisions. So much for that argument. By now it was 1972; NHTSA had been researching and analyzing for four years to answer Ford’s objections. During that time, nearly 9,000 people burned to death in flaming wrecks. Tens of thousands more were badly burned and scarred for life. And the four-year delay meant that well over 10 million new unsafe vehicles went on the road, vehicles that will be crashing, leaking fuel and incinerating people well into the 1980s.

Ford now had to enter its third round of battling the new regulations. On the “the problem is not X but Y” principle, the company had to look around for something new to get itself off the hook. One might have thought that, faced with all the latest statistics on the horrifying number of deaths in flaming accidents, Ford would find the task difficult. But the company’s rhetoric was brilliant. The problem was not burns, but…impact! Most of the people killed in these fiery accidents, claimed Ford, would have died whether the car burned or not. They were killed by the kinetic force of the impact, not the fire.

And so once again, as in some giant underwater tennis game, the ball bounced into the government’s court and the absurdly pro-industry NHTSA began another slow-motion response. Once again it began a time-consuming round of test crashes and embarked on a study of accidents. The latter, however, revealed that a large and growing number of corpses taken from burned cars involved in rear-end crashes contained no cuts, bruises or broken bones. They clearly would have survived the accident unharmed if the cars had not caught fire. This pattern was confirmed in careful rear-end crash tests performed by the Insurance Institute for Highway Safety. A University of Miami study found an inordinate number of Pintos burning on rear-end impact and concluded that this demonstrated “a clear and present hazard to all Pinto owners.”

Pressure on NHTSA from Ralph Nader and consumer groups began mounting. The industry-agency collusion was so obvious that Senator Joseph Montoya (D-N.M.) introduced legislation about Standard 301. NHTSA waffled some more and again announced its intentions to promulgate a rear-end collision standard.

Waiting, as it normally does, until the last day allowed for response, Ford filed with NHTSA a gargantuan batch of letters, studies and charts now arguing that the federal testing criteria were unfair. Ford also argued that design changes required to meet the standard would take 43 months, which seemed like a rather long time in light of the fact that the entire Pinto was designed in about two years. Specifically, new complaints about the standard involved the weight of the test vehicle, whether or not the brakes should be engaged at the moment of impact and the claim that the standard should only apply to cars, not trucks or buses. Perhaps the most amusing argument was that the engine should not be idling during crash tests, the rationale being that an idling engine meant that the gas tank had to contain gasoline and that the hot lights needed to film the crash might ignite the gasoline and cause a fire.

Some of these complaints were accepted, others rejected. But they all required examination and testing by a weak-kneed NHTSA, meaning more of those 18-month studies the industry loves so much. So the complaints served their real purpose—delay; all told, an eight-year delay, while Ford manufactured more than three million profitable, dangerously incendiary Pintos. To justify this delay, Henry Ford II called more press conferences to predict the demise of American civilization. “If we can’t meet the standards when they are published,” he warned, “we will have to close down. And if we have to close down some production because we don’t meet standards we’re in for real trouble in this country.”

While government bureaucrats dragged their feet on lifesaving Standard 301, a different kind of expert was taking a close look at the Pinto—the “recon man.” “Recon” stands for reconstruction; recon men reconstruct accidents for police departments, insurance companies and lawyers who want to know exactly who or what caused an accident. It didn’t take many rear-end Pinto accidents to demonstrate the weakness of the car. Recon men began encouraging lawyers to look beyond one driver or another to the manufacturer in their search for fault, particularly in the growing number of accidents where passengers were uninjured by collision but were badly burned by fire.

Pinto lawsuits began mounting fast against Ford. Says John Versace, executive safety engineer at Ford’s Safety Research Center, “Ulcers are running pretty high among the engineers who worked on the Pinto. Every lawyer in the country seems to want to take their depositions.” (The Safety Research Center is an impressive glass and concrete building standing by itself about a mile from Ford World Headquarters in Dearborn. Looking at it, one imagines its large staff protects consumers from burned and broken limbs. Not so. The Center is the technical support arm of Jack Echold’s 14-person anti-regulatory lobbying team in World Headquarters.)

When the Pinto liability suits began, Ford strategy was to go to a jury. Confident it could hide the Pinto crash tests, Ford thought that juries of solid American registered voters would buy the industry doctrine that drivers, not cars, cause accidents. It didn’t work. It seems that juries are much quicker to see the truth than bureaucracies, a fact that gives one confidence in democracy. Juries began ruling against the company, granting million-dollar awards to plaintiffs.

“We’ll never go to a jury again,” says Al Stechter in Ford’s Washington office. “Not in a fire case. Juries are just too sentimental. They see those charred remains and forget the evidence. No sir, we’ll settle.”

Settlement involves less cash, smaller legal fees and less publicity, but it is an indication of the weakness of their case. Nevertheless, Ford has been settling when it is clear that the company can’t pin the blame on the driver of the other car. But, since the company carries $2 million deductible product-liability insurance, these settlements have a direct impact on the bottom line. They must therefore be considered a factor in determining the net operating profit on the Pinto. It’s impossible to get a straight answer from Ford on the profitability of the Pinto and the impact of lawsuit settlements on it—even when you have a curious and mildly irate shareholder call to inquire, as we did. However, financial officer Charles Matthews did admit that the company establishes a reserve for large dollar settlements. He would not divulge the amount of the reserve and had no explanation for its absence from the annual report.

Until recently, it was clear that, whatever the cost of these settlements, it was not enough to seriously cut into the Pinto’s enormous profits. The cost of retooling Pinto assembly lines and of equipping each car with a safety gadget like that $5.08 Goodyear bladder was, company accountants calculated, greater than that of paying out millions to survivors like Robbie Carlton or to widows and widowers of victims like Sandra Gillespie. The bottom line ruled, and inflammable Pintos kept rolling out of the factories.

In 1977, however, an incredibly sluggish government has at last instituted Standard 301. Now Pintos will have to have rupture-proof gas tanks. Or will they?

To everyone’s surprise, the 1977 Pinto recently passed a rear-end crash test in Phoenix, Arizona, for NHTSA. The agency was so convinced the Pinto would fail that it was the first car tested. Amazingly, it did not burst into flame.

“We have had so many Ford failures in the past,” explained agency engineer Tom Grubbs, “I felt sure the Pinto would fail.”

How did it pass?

Remember that one-dollar, one-pound plastic baffle that was on one of the three modified Pintos that passed the pre-production crash tests nearly ten years ago? Well, it is a standard feature on the 1977 Pinto. In the Phoenix test it protected the gas tank from being perforated by those four bolts on the differential housing.

We asked Grubbs if he noticed any other substantial alterations in the rear-end structure of the car. “No,” he replied, “the

But was it? What Tom Grubbs and the Department of Transportation didn’t know when they tested the car was that it was manufactured in St. Thomas, Ontario. Ontario? The significance of that becomes clear when you learn that Canada has for years had extremely strict rear-end collision standards.

Tom Irwin is the business manager of Charlie Rossi Ford, the Scottsdale, Arizona, dealership that sold the Pinto to Tom Grubbs. He refused to explain why he was selling Fords made in Canada when there is a huge Pinto assembly plant much closer by in California. “I know why you’re asking that question, and I’m not going to answer it,” he blurted out. “You’ll have to ask the company.”

But Ford’s regional office in Phoenix has “no explanation” for the presence of Canadian cars in their local dealerships. Farther up the line in Dearborn, Ford people claim there is absolutely no difference between American and Canadian Pintos. They say cars are shipped back and forth across the border as a matter of course. But they were hard pressed to explain why some Canadian Pintos were shipped all the way to Scottsdale, Arizona. Significantly, one engineer at the St. Thomas plant did admit that the existence of strict rear-end collision standards in Canada “might encourage us to pay a little more attention to quality control on that part of the car.”

The Department of Transportation is considering buying an American Pinto and running the test again. For now, it will only say that the situation is under investigation.

Whether the new American Pinto fails or passes the test, Standard 301 will never force the company to test or recall the more than two million pre-1977 Pintos still on the highway. Seventy or more people will burn to death in those cars every year for many years to come. If the past is any indication, Ford will continue to accept the deaths.

According to safety expert Byron Bloch, the older cars could quite easily be retrofitted with gas tanks containing fuel cells. “These improved tanks would add at least 10 mph improved safety performance to the rear end,” he estimated, “but it would cost Ford $20 to $30 a car, so they won’t do it unless they are forced to.” Dr. Kenneth Saczalski, safety engineer with the Office of Naval Research in Washington, agrees. “The Defense Department has developed virtually fail-safe fuel systems and retrofitted them into existing vehicles. We have shown them to the auto industry and they have ignored them.”

Unfortunately, the Pinto is not an isolated case of corporate malpractice in the auto industry. Neither is Ford a lone sinner. There probably isn’t a car on the road without a safety hazard known to its manufacturer. And though Ford may have the best auto lobbyists in Washington, it is not alone. The anti-emission control lobby and the anti-safety lobby usually work in chorus form, presenting a well-harmonized message from the country’s richest industry, spoken through the voices of individual companies—the Motor Vehicle Manufacturers Association, the Business Council and the U.S. Chamber of Commerce.

Furthermore, cost-valuing human life is not used by Ford alone. Ford was just the only company careless enough to let such an embarrassing calculation slip into public records. The process of willfully trading lives for profits is built into corporate capitalism. Commodore Vanderbilt publicly scorned George Westinghouse and his “foolish” air brakes while people died by the hundreds in accidents on Vanderbilt’s railroads.

The original draft of the Motor Vehicle Safety Act provided for criminal sanction against a manufacturer who willfully placed an unsafe car on the market. Early in the proceedings the auto industry lobbied the provision out of the bill. Since then, there have been those damage settlements, of course, but the only government punishment meted out to auto companies for noncompliance to standards has been a minuscule fine, usually $5,000 to $10,000. One wonders how long the Ford Motor Company would continue to market lethal cars were Henry Ford II and Lee Iacocca serving 20-year terms in Leavenworth for consumer homicide.

Its one thing helping a business with an otherwise good reputation who has made a one off mistake and wants to make it right, or helping one that has been a victim of deformation than it is to help rogue traders continue to rip off the consumer and whilst we at Edible will help the former, we will not help the later.

If you want to discuss Online Reputation Management or review your online reputation get in touch with Edible for further details and a free, no obligation consultation.